Concrete in Industrial Design

It is near impossible to make concrete product design attractive. A few examples below show excellent attempts, but concrete is inherently ugly.

Industrial Designers have affinity for do-it-yourself material. For example there is a lot of cardboard, paper, fabric and bent wire furniture, these materials are readily available and require only basic craft tools to form into usable shapes. A common university ID studio assignment is to explore 3D form development with these materials.

Also, of course, Industrial Designers have affinity to materials of industry, and concrete is the most ubiquitous industrial material, much more than plastics or metals.

Core77 Industrial Design site search returns 10 pages on “concrete”, some as adjective “concrete deliverable”. Of actual concrete material product design, 40% architectural, 30-40% one-off experimental craft designs, the products shown include lamps, furniture, home and desk accessories, and a few personal items like jewelry and pens. Design sites Booom and Yanko return even less, but show similar product types.

Concrete dates from 1400-1200 BC in a Greek royal palace.

The Roman amphitheater and Pantheon are partially concrete construction.

Concrete is a composite material composed mainly of water, aggregate, and cement. The concrete hardens through a chemical process called hydration, water reacts with the cement which bonds the other components together, creating a robust stone-like material. Cement is the important ingredient in our discussion here on uglyness.

Portland cement is the most common type of cement in general usage. It is a basic ingredient of concrete, mortar and plaster. English masonry worker Joseph Aspdin patented Portland cement in 1824. It was named because of the similarity of its color to Portland limestone, quarried from the English Isle of Portland and used extensively in London architecture. It consists of a mixture of oxides of calcium, silicon and aluminium. Portland cement and similar materials are made by heating limestone (a source of calcium) with clay and grinding this product (called clinker) with a source of sulfate (most commonly gypsum).

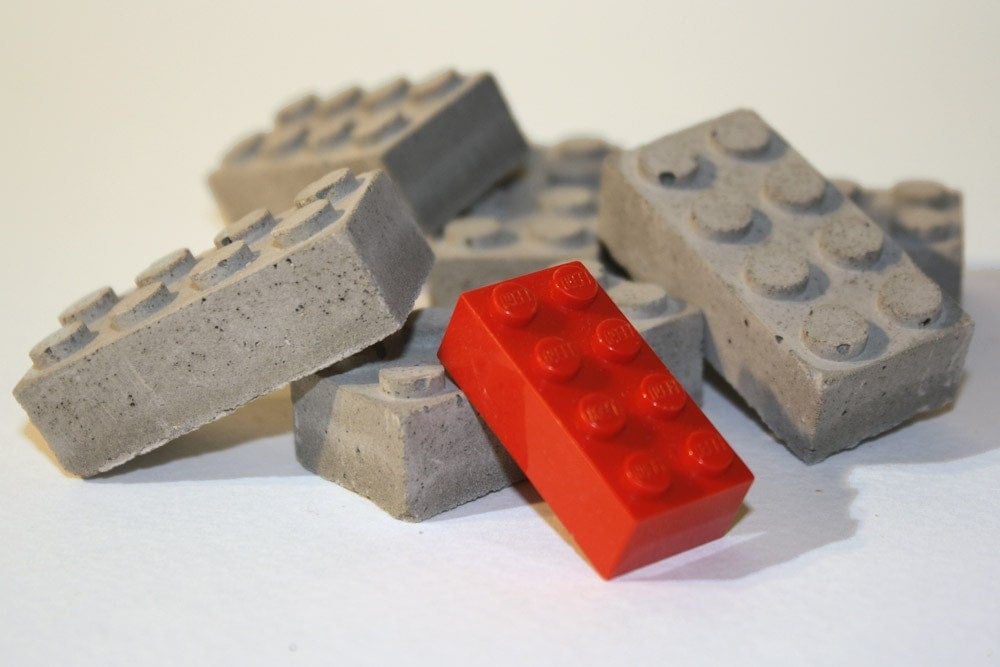

The aggregate, usually gravel or sand, is often omitted in these Industrial Design examples for moldability and smooth surface finish.

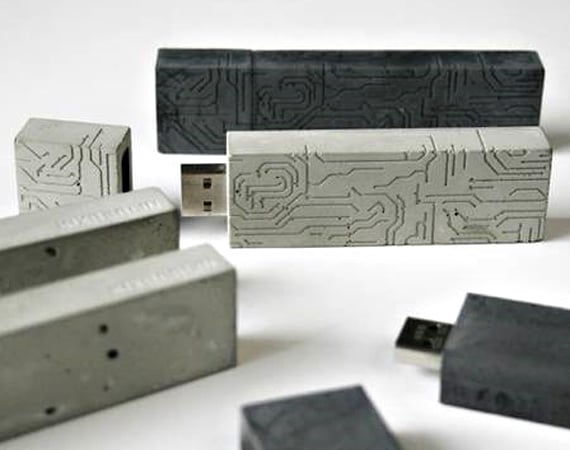

Cement: calcium, silicon, aluminium, clay and gypsum, all dull grey.

Wikipedia quote on cement is key, all ingredients are dull grey. Calcium is white to dirty off white, silicon is a very cold dark grey, aluminium is a cold metallic silver. Concrete colour is integrally cold, even when heavily coloured concrete exudes a cold mien, the dull chroma of original cold grey cannot be overcome.

Concrete can be successfully coloured with a high load, but similar to plastics fill, it affects the moldability by increasing viscosity which also affects cure time, and changes ratio of the mix which affects concrete strength.

In concrete mix the water is binder and gap filler, but due to cements fine powder state and the hydration process, air bubbles and voids are inherent. Concrete texture is uninviting, no tactile invitation, and stains easily unless sealed.

Concrete is strong when properly mixed, poured and cured, but like all stone, edges and corners are rough, chipped or show inherent bubbles and voids, observable in examples here.

There are no industrial processing methods of concrete, all part molding shown here is hand poured into wood temporary forms, there isn’t any demand and it’s so abrasive machine parts would wear too quickly.

Recent news feature 3D printing concrete house structure. This is a small adaptation of existing construction equipment and different concrete recipe. Also, the concrete is covered with other wall finishes as concrete is ugly.

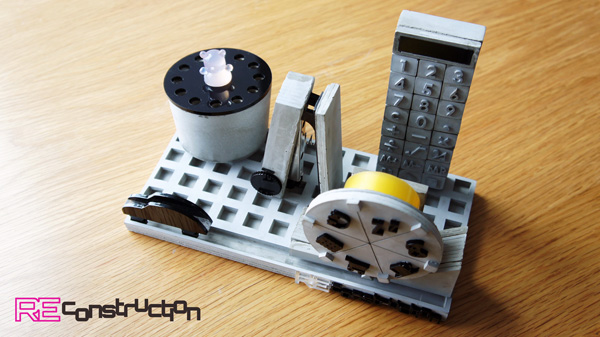

Concrete Industrial Design we like!

Lamps and graves, light and dark! This pendant lamp is a simple shape, but the rough juxtaposition of cold concrete and warm glass is well done. The grave markers are exquisite design and concrete is an acceptable material choice as it will wear appropriately with time.